DISCOVER SAFETY, SAVINGS, AND SMARTER OPERATIONS

Maximize Uptime. Minimize Risk. Optimize Your Shop with a Free JET Site Assessment.

Whether you are a job shop, maintenance department, school, or machine shop, we tailor the assessment to your specific environment and needs. The JET Site Assessment is a quick, no-cost review of your tools, machinery, and facility equipment — focused on identifying risks, enhancing safety, optimizing performance, and uncovering potential savings. Our team tailors the assessment to your specific environment and operational goals.

WHY CHOOSE A SITE ASSESSSMENT FROM JET?

A JET Site Assessment is more than a walkthrough—it's a fast, no-cost way to uncover safety risks, streamline your workflow, and spot savings you didn't know were there. Our experts evaluate your tools, equipment, and processes to deliver real-world recommendations that improve uptime, compliance, and performance.

COMPREHENSIVE

EQUIPMENT

REVIEW

- A full look at your current machinery to ensure every tool is safe, compliant, and optimized for daily operations.

COST-SAVING

PROCESS

DIRECTION

- Recommendations to save time and consumables — for example, step-ups like power-feeds and air-powered drawbars on JET mills or adding a JET Ironworker to punch holes and shear angle iron.

EXPERT PRODUCT

UPGRADE

INSIGHTS

- Guidance on capacity and workflow improvements, such as semi-automatic band saws or wide-belt sanders, to boost output and quality.

OSHA &

SAFETY RISK

IDENTIFICATION

- Spotting hazards such as missing guards, leaks, worn parts, broken E-Stops, or missing foot-brakes — plus safety add-ons like JET’s chuck-key holder for lathes.

STRATEGIC

DOCUMENTATION

FOR PLANNING

- Detailed follow-up report with specs, power requirements, and recommendations so you can budget and prioritize immediate and long-term upgrades.

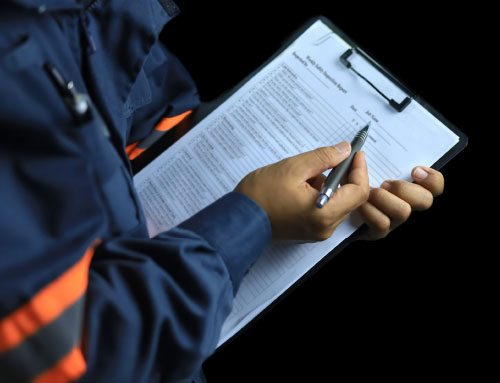

JET SITE ASSESSMENT PROCESS

A JET Site Assessment is more than a walkthrough—it's a fast, no-cost way to uncover safety risks, streamline your workflow, and spot savings you didn't know were there. Our experts evaluate your tools, equipment, and processes to deliver real-world recommendations that improve uptime, compliance, and performance.

We coordinate with your knowledgeable team members to walk through your facility and inspect critical equipment.

We document key details about your tools and machines, including facility type, usage, condition, and safety status.

You'll receive a comprehensive report with: Safety & OSHA compliance insights, process and ergonomic improvement opportunities, and product recommendations based on needs and risks.